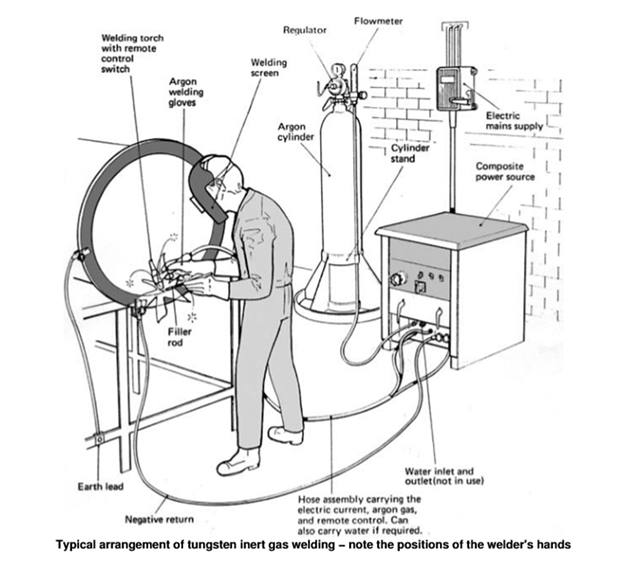

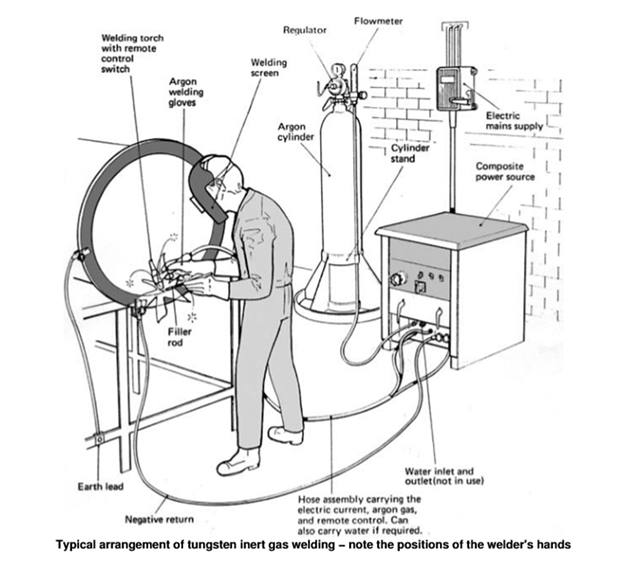

Gas tungsten arc welding. Gas tungsten arc welding GTAW also known as tungsten inert gas TIG welding is an arc welding process that uses a non-consumable tungsten electrode to produce the weldThe weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas argon or heliumA filler metal is normally used though some welds known as autogenous welds or.

What Is Tungsten Inert Gas Gtaw Or Tig Welding Twi

Gas Tungsten Arch Welding Gtaw Process Eurotech Trainings

The Fundamentals Of Gas Tungsten Arc Welding Preparation Consumables And Equipment Necessary For The Process

Co2 welding gmaw or mig or mag Metal inert gas welding process.

Gas tungsten arc welding process. In this kind of welding process the arc will generate among the work part as well as the tungsten electrode. The choice of current and polarity depends on the process the type of electrode the arc atmosphere and the metal being welded. AKA Gas Tungsten Arc Welding GTAW TIG welding is a type of welding process in which the welding arc occurs between a tungsten electrode and the workpiece.

Best mig welding machine with their feature. You need to hold the tungsten electrode about an eighth of an inch away from the workpiece. View Arc Welding How-To articles.

Mig welding machine uses. A power supply creates an electric arc between a consumable or non-consumable electrode and the base material using either direct DC or alternating AC currents. Using an inert gas shield instead of a slag to protect the weldpool the process was a highly attractive replacement for gas and manual metal arc welding.

Graduates of the Welding program will be able to demonstrate competencies in flame cutting electric ARC welding gas tungsten gas metal ARC welding and flux-cored ARC welding processes. Among the numerous different types of welding processes available today gas tungsten arc welding or GTAW is generally considered the most challenging welding method to master. TIG stands for tungsten inert gas and GTAW stands for gas tungsten arc welding.

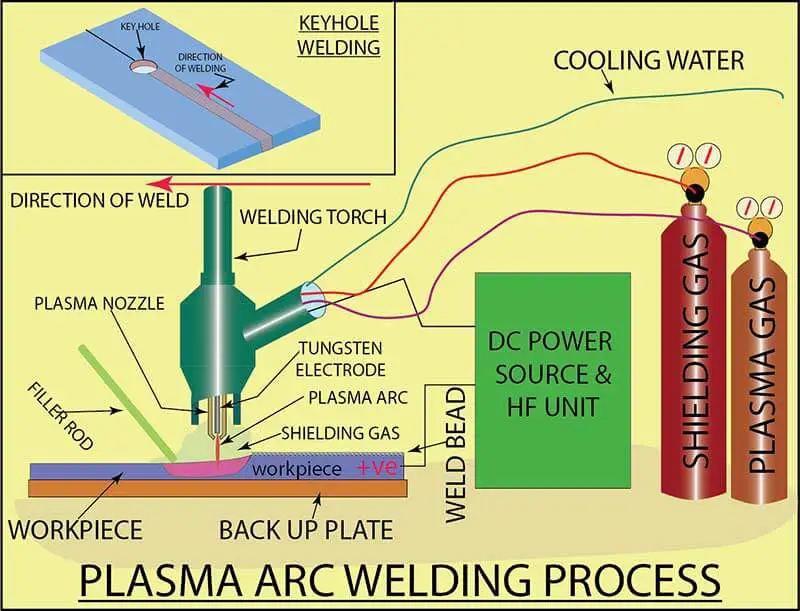

GTAW was the official name at one time but it is now commonly referred to as TIG. The process uses shielding from an externally supplied gas to protect the molten weld pool. Plasma arc welding PAW is similar to GTAW or gas tungsten welding.

TIG welding gases are inert gases used as shielding gases in the TIG welding process. Arc welding may be done with direct current DC with the electrode either positive or negative or alternating current AC. The tungsten electrode is a critical component in the process as it channels the current required to establish the arc.

With this in mind we offer an extensive range of mig wire tig rods electrodes and gas welding. It is an arc-welding process that uses a fixed consumable tungsten electrode to produce the weld. In hindi Mig 250f 3-ph with feeder welding machine working principle.

Although it is more time consuming than other welding methods even when practiced with the care of an expert the improved strength and quality of welds produced with GTAW can offer a practical alternative to. TIG welding stands for tungsten inert gas arc welding from American welding society it is also identified as GTAW. MIG-205DS 3-in-1 multi-process dual-voltage synergic welder is powerful helper in welding The IGBT inverter technology provides high power in a light compact unit 33 lbsits designed for for hardware decoration car modification equipment and factory maintenance This units are capable of performing mig lift tig and stick welding.

Progression is monitored and mastery of each technique is achieved by a combination of classroom individual and text book instruction. Process Definition Gas Metal Arc Welding GMAW by definition is an arc welding process which produces the coalescence of metals by heating them with an arc between a con-tinuously fed filler metal electrode and the work. This process is much more time consuming than MIG Stick or Flux Cored Arc Welding.

Gas metal arc welding GMAW sometimes referred to by its subtypes metal inert gas MIG and metal active gas MAG is a welding process in which an electric arc forms between a consumable MIG wire electrode and the workpiece metals which heats the workpiece metals causing them to fuse melt and join. View more Arc Welding Process and Theory articles. The GTAW process relies on tungstens hardness and high-temperature resistance to carry the welding current to the arc.

Gas Tungsten Arc Welding GTAWTIG Welding together thick sections of stainless steel or non-ferrous metals is the most common use for this method. TIG welding gas is also used with gas tungsten arc welding GTAW using a tungsten electrode and argon shielding gas. Tungsten is a rare metallic element used for manufacturing gas tungsten arc welding GTAW electrodes.

Mig welding equipment specification. Arc welding is a type of welding process using an electric arc to create heat to melt and join metals. Shielded metal arc welding is a various process ideal for joining ferrous and non-ferrous materials with the thickness of the material at all positions.

What is TIG Welding. An even less common name for GTAW is argon welding. Along with the wire electrode a shielding gas feeds through the welding gun which.

Welding Products including TIG welders MIG welders Stick welders and Plasma cutter products from Everlast Power Equipment are gaining national recognition and worldwide acceptance. This welding process is likewise called as gas welding. If Everlast is a new name to you or you are curious about our inverter welders plasma cutters welding product line we hope that you find this site helpful.

Tungsten has the highest melting point. The tungsten electrode is held in a collet inside of the welding torch. These include but are not limited to the following and the pulsed derivate.

This process specification is applicable to fusion arc solid-state resistance and high-energy density weld processes for joining metallic materials. In this type of process shielding gas is used for welding. Leading the way in a new era of the welding industry.

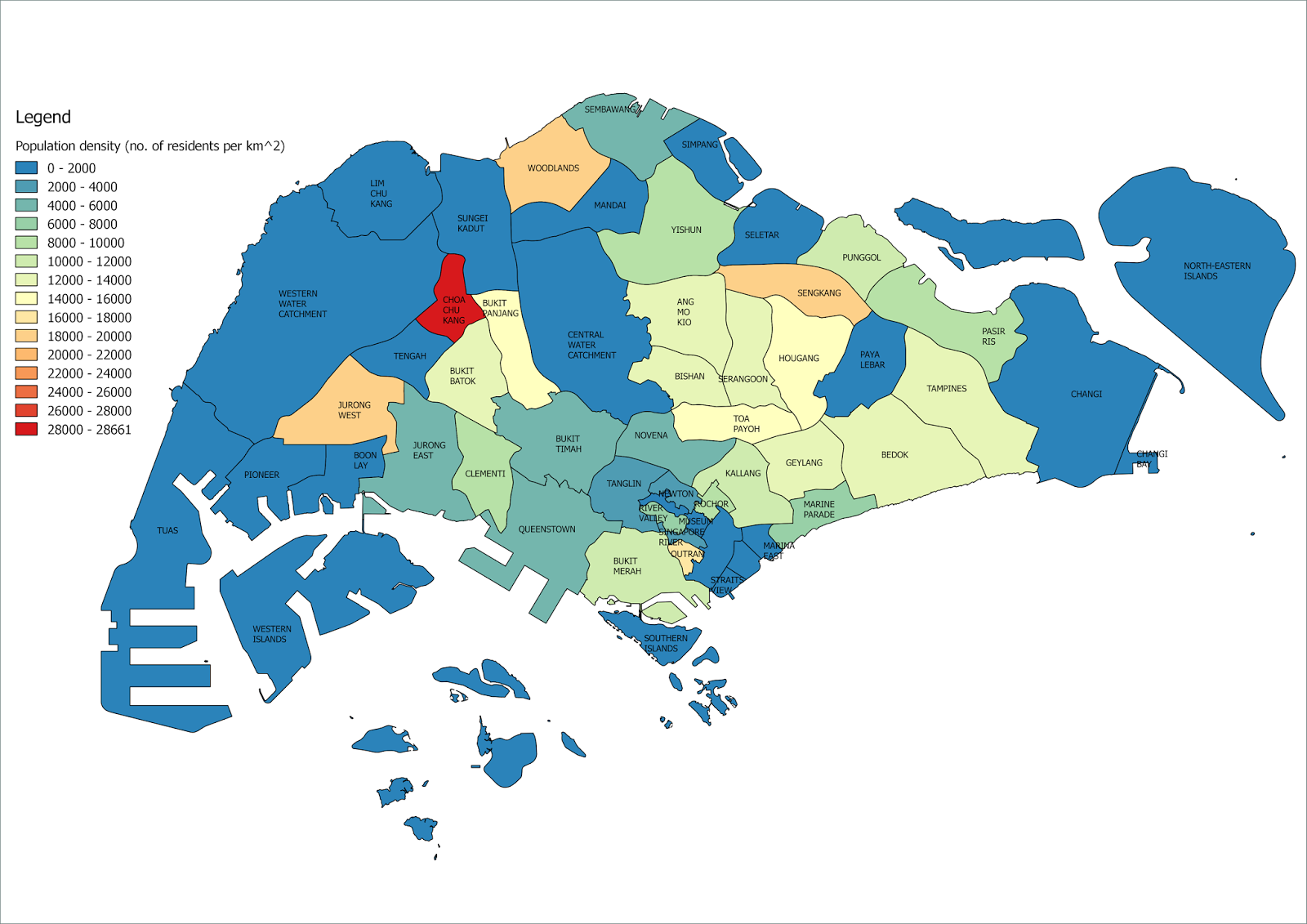

Tungsten inert gas TIG welding became an overnight success in the 1940s for joining magnesium and aluminium. Gas tungsten arc welding GTAW or TIG welding Your metal and the type of weld youre hoping to achieve determine the best welder for your purpose. Some welders are better suited for large structural welds while others are best for detailed surface welds that are easy to buff to a flawless finish.

Steel stainless steel cast iron bronze aluminium hardfacing and many other welding materials for the more sophisticated alloys. What is TIG Welding Process or Gas Tungsten Arc Welding GTAW Explosive Welding Equipment Types Working Advantages and Disadvantages with Application. Tungsten Inert Gas TIG welding is a popular type of welding that utilizes tungsten electrodes to join various metals.

The major dissimilarity between plasma arc welding and gas tungsten welding is that the electrode is located within the torch of Plasma arc welding. TIGGTAW uses tungsten electrodes in the welding process. The MIG welding process is based on the principle that a consumable metal electrode is used to produce an arc in between the metal electrode and the workpiece.

Argon shielding gas protects the weld pool from. Miller Welding Engineer Zack Erndt explains the benefits of using pulse when TIG welding and talks about applications where low and high pulses per second can be. Processes 215994 F 2018-01 Guidelines For Gas Tungsten Arc Welding GTAW TIG GTAW Welding For product information Owners Manual translations and more visit.

1 FCAW - Flux-Cored Arc Welding 2 GMAW - Gas Metal Arc Welding 3 GTAW - Gas Tungsten Arc Welding. We understand that welding equipment is of no use unless we also provide the welding materialsconsumables to go with it. Practical of mig welding machine.

Mig welding machines process and tips.

Schematic Of Gas Tungsten Arc Welding Gas Tungsten Arc Welding Arc Welding Welding

2 Gas Tungsten Arc Welding Gtaw Process Download Scientific Diagram

7 1 The Gas Tungsten Arc Welding Station Halverson Cts

What Is Gtaw In Welding Qa Qc Professionals

Advances In Gas Tungsten Arc Welding Processes Weld Fab Tech Times

Tig Welding Gas Tungsten Arc Welding Sparker Electric Ltd

Gas Tungsten Arc Welding Gtaw How It S Made

Principle Of Plasma Arc Welding And Differences From Gtaw Tig